Top Automatic Injection Mould Component Manufacturers in Chennai – Precision & Quality

Our Benefits of Automatic Plastic Injection Moulding Parts in Chennai

✅ High Precision & Consistency – Ensures uniform and accurate production of complex plastic parts with minimal errors.

✅ Faster Production Cycle – Automated moulding speeds up manufacturing, allowing high-volume production in less time.

✅ Cost-Effective Manufacturing – Reduces labor costs, material waste, and energy consumption, leading to lower production costs.

✅ Enhanced Durability & Strength – Produces high-quality, durable plastic components suitable for various industries.

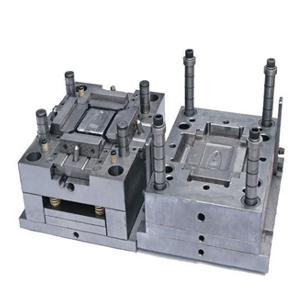

If you are looking for reliable Automatic Plastic Injection Mould Manufacturers in Chennai, you’ve come to the right place. Chennai is home to some of the leading manufacturers that specialize in precision-engineered injection moulds for a wide range of industries, including automotive, electronics, packaging, medical, and consumer goods. These manufacturers combine advanced technology with industry expertise to deliver high-quality, durable, and cost-effective plastic injection moulds that meet the specific needs of their clients.

Our Plastic Moulded Parts Solutions:

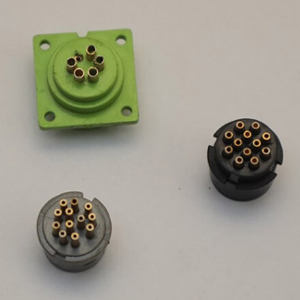

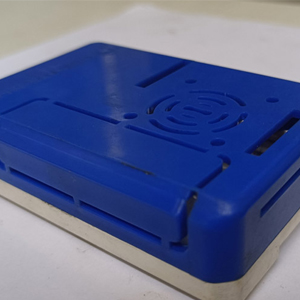

✔ Injection Moulded Parts – High-precision components with complex designs.

✔ Compression Moulded Parts – Durable and heat-resistant plastic parts.

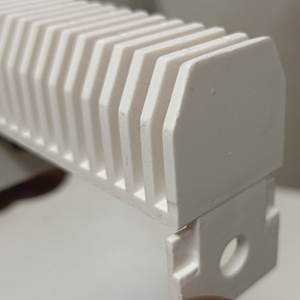

✔ Extrusion Moulded Parts – Consistent and uniform plastic profiles.

✔ Custom Moulded Parts – Tailored solutions to meet specific industry needs.

Why Choose Automatic Injection Mould Components?

Automatic injection moulding improves productivity by minimizing manual intervention. Key benefits include:

✅ Higher Efficiency – Automated systems reduce cycle times and increase output.

✅ Consistent Quality – Precision components ensure uniform product dimensions.

✅ Reduced Labor Costs – Automation decreases dependency on manual labor.

✅ Lower Defect Rates – Advanced moulding techniques minimize errors.

✅ Faster Production – Ideal for high-volume manufacturing needs.