Top Plastic Die Manufacturers in Chennai | I Tech Moulds – Reliable Die Solutions

Top Plastic Die Manufacturers in Chennai: Excellence in Precision and Quality

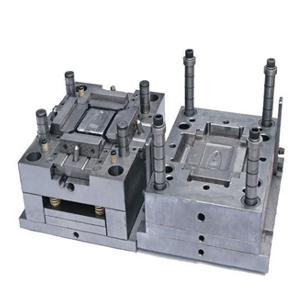

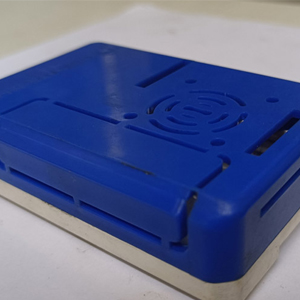

Plastic Die Manufacturers in Chennai – I Tech Moulds is a No.1 Manufacturers of Plastic Die ,Plastic Mould, Tool and Die in Ekkaduthangal, Guindy, Chennai.

Looking for top-tier plastic die manufacturers in Chennai? Your search ends here! In this comprehensive guide, we’ll walk you through everything you need to know to locate the best plastic die manufacturers in Chennai. From understanding the importance of plastic dies to key factors to consider when choosing a manufacturer, we’ve got you covered. Plastic Die Manufacturers in Chennai – I Tech Moulds is the No.1 Manufacturers of Plastic Die, Plastic Mould, Tool, and Die in Ekkaduthangal, Guindy, Chennai.

When it comes to plastic die manufacturing, precision and quality are paramount. In Chennai, some of the best plastic die manufacturers are setting industry standards by delivering products that meet the most demanding specifications